Optional Accessories

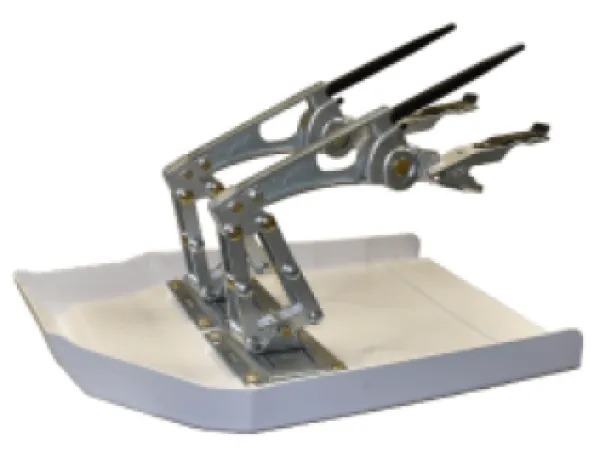

This pan attaches to the rail of the Flexxfinger’s® line of crop lifters and helps to:

- Pull edible bean pods above the knife

- Reduce shatter loss in dry field conditions by catching shelled seed that would otherwise be lost

This custom carriage bolt is for select headers that have a poly skid plate held on by a 7/16” (11mm) carriage step bolt from under the header. Our 32310 carriage bolt is 7/16" with the extra step and tapers to 10mm to fit the QD™ nut.

This custom carriage bolt is for a header that uses a 7/16” (11mm) carriage bolt from under the header. Our 32312 carriage bolt is 7/16" and tapers to 10mm to fit the QD™ nut.

This Carriage bolt is used on a header that has a 10mm guard bolt from under the header and fits the QD™ nut.

On headers that have 4”(100mm) spacing between the guards, there will be instances where the guard bolts do not line up with the guard point, making the installation of a lifter at specific intervals impossible. Flexxifinger® has engineered a patented bracket, to position a lifter on a guard tip that does not align with a bolt. This allows users to place Flexxifinger® lifters at intervals other than once every 12” (304mm).

See if this product is right for you.

Try our product selectorThe FlexxiFloat™ crop lifter series have a spring-pivot which allows the lifter to follow the fluctuations of the ground, making it ideal for uneven ground conditions. The FlexxiFloat™ system is available with three rail options: the standard rail, the high-pivot rail, and the high-pivot MD-2 rail. The standard rail is generally used with a rigid header, while the high-pivot rail is used with a flex header, with the exception of a few specific makes and models of header and feeder house combinations. The high-pivot MD-2 rail fits the MacDon® #286315 long guard.

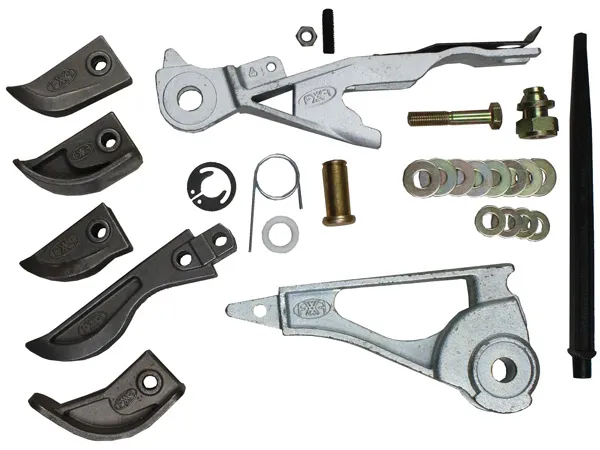

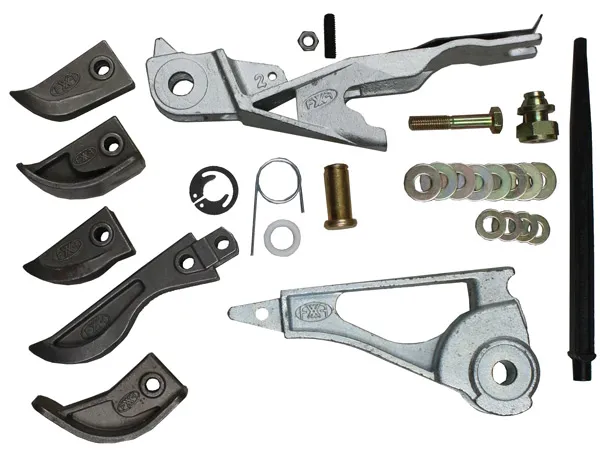

The FlexxiFloat™ 200 is used in crops with a shorter stand and/or where the plants are more delicate, such as lentils, peas and beans. Made of sturdy cast metal, this lifter is capable of standing up to the most challenging ground conditions.

Benefits

Usage

Crop type: peas, lentils, chickpeas, black beans, pinto beans, soy beans, white beans

Because the FlexxiFloat™ 200 is an all metal lifter, caution must be exercised by the combine operator to minimize the potential of damaging the header/ combine.

General recommendation is one lifter per foot across the header for solid-seeded crops. For maximum efficiency, lifters spacing may be customized to fit various row crop configurations. Lifter spacing depends on row spacing, and whether entering the field with the rows, or on an angle.

** Some or all of these components are made of steel, therefore care must be exercised by the combine operator to minimize possible damage to the header/ combine.**