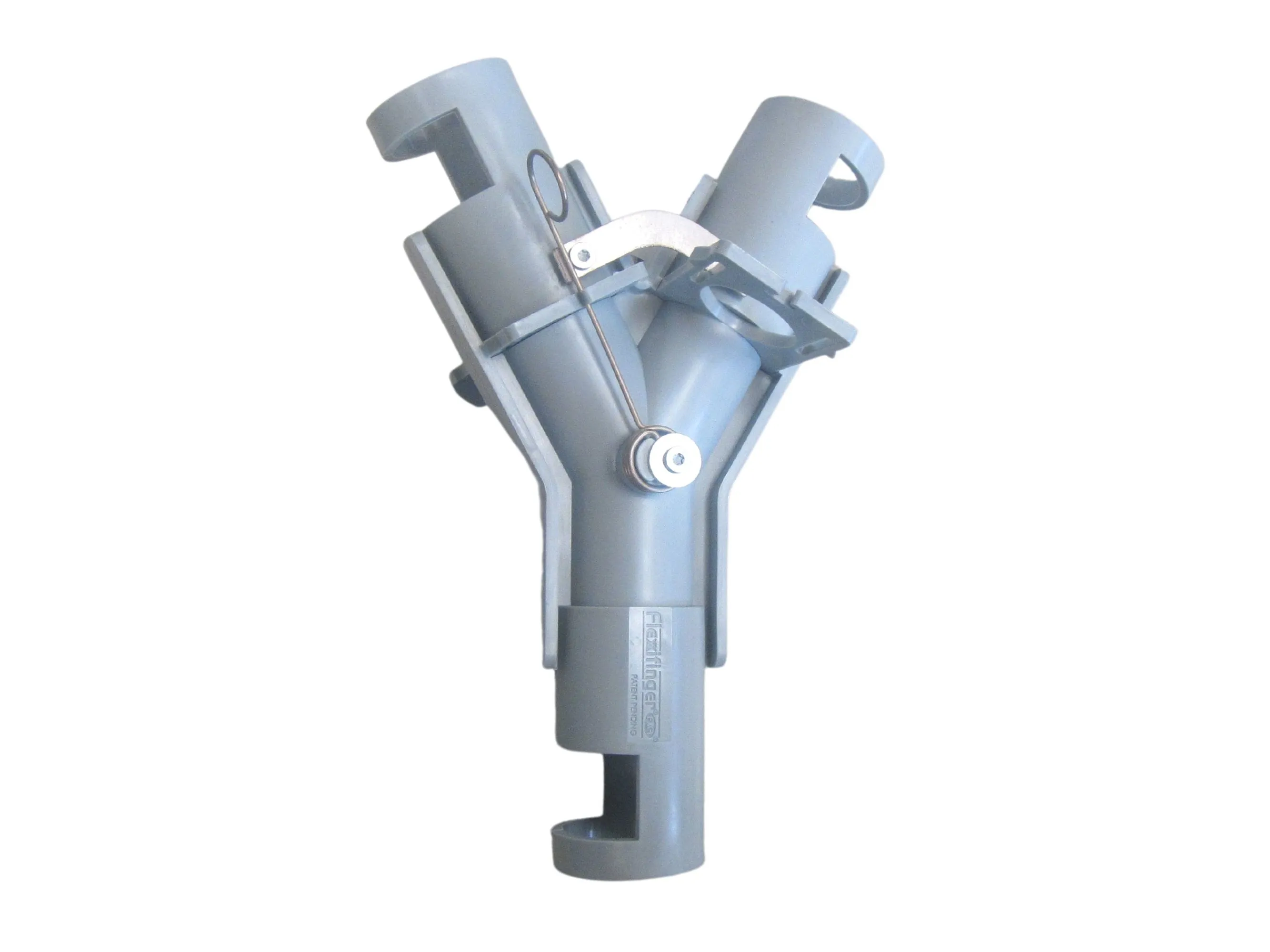

MultiCrop Valve™

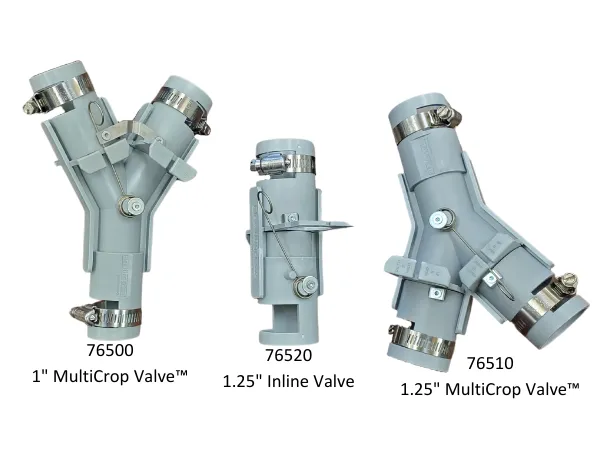

76500 Flexxifinger® MultiCrop Valve™

Features

Specifications

Videos & Guides

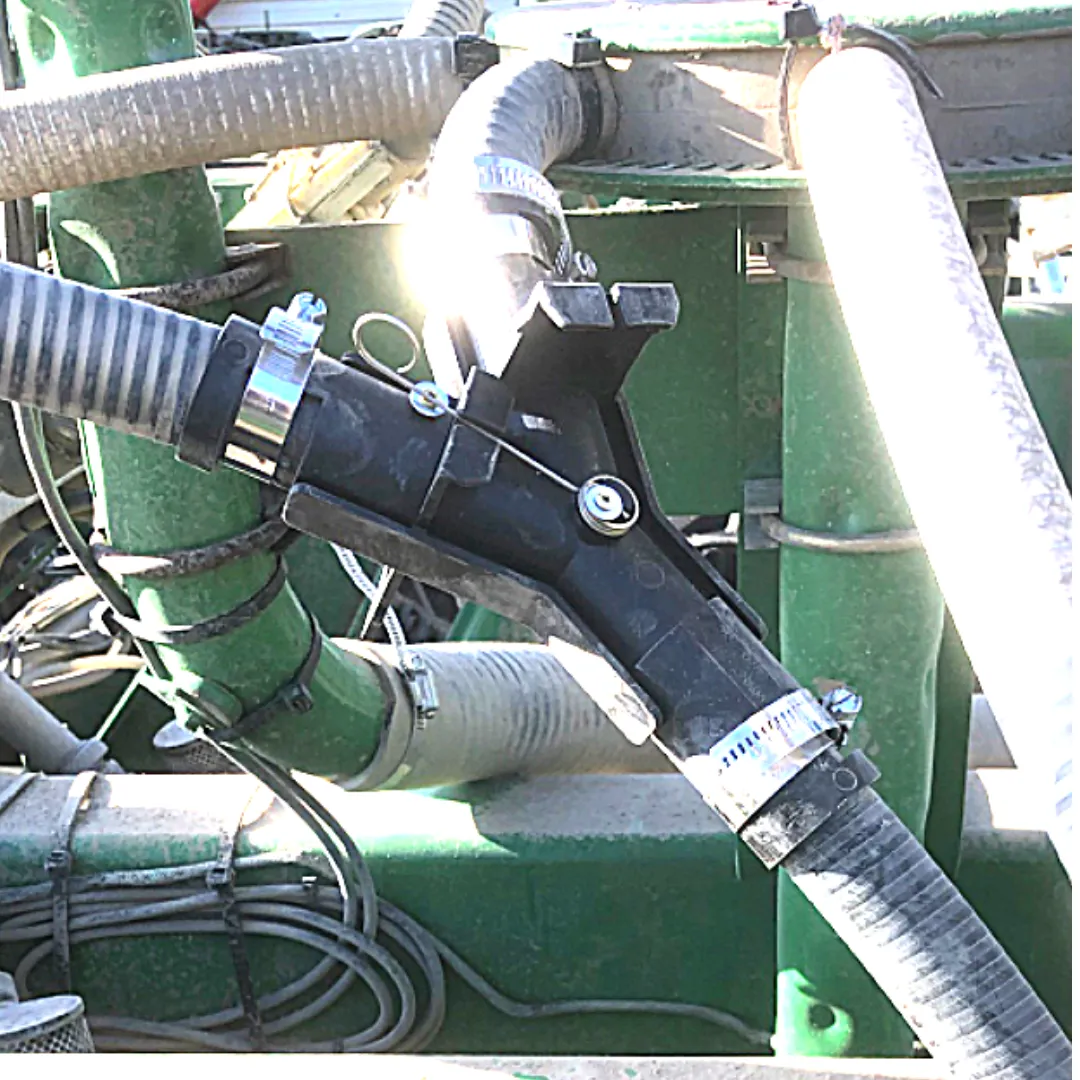

- Easily and quickly switch from mono-crop to multi-crop seeding with precision, using the same air drill.

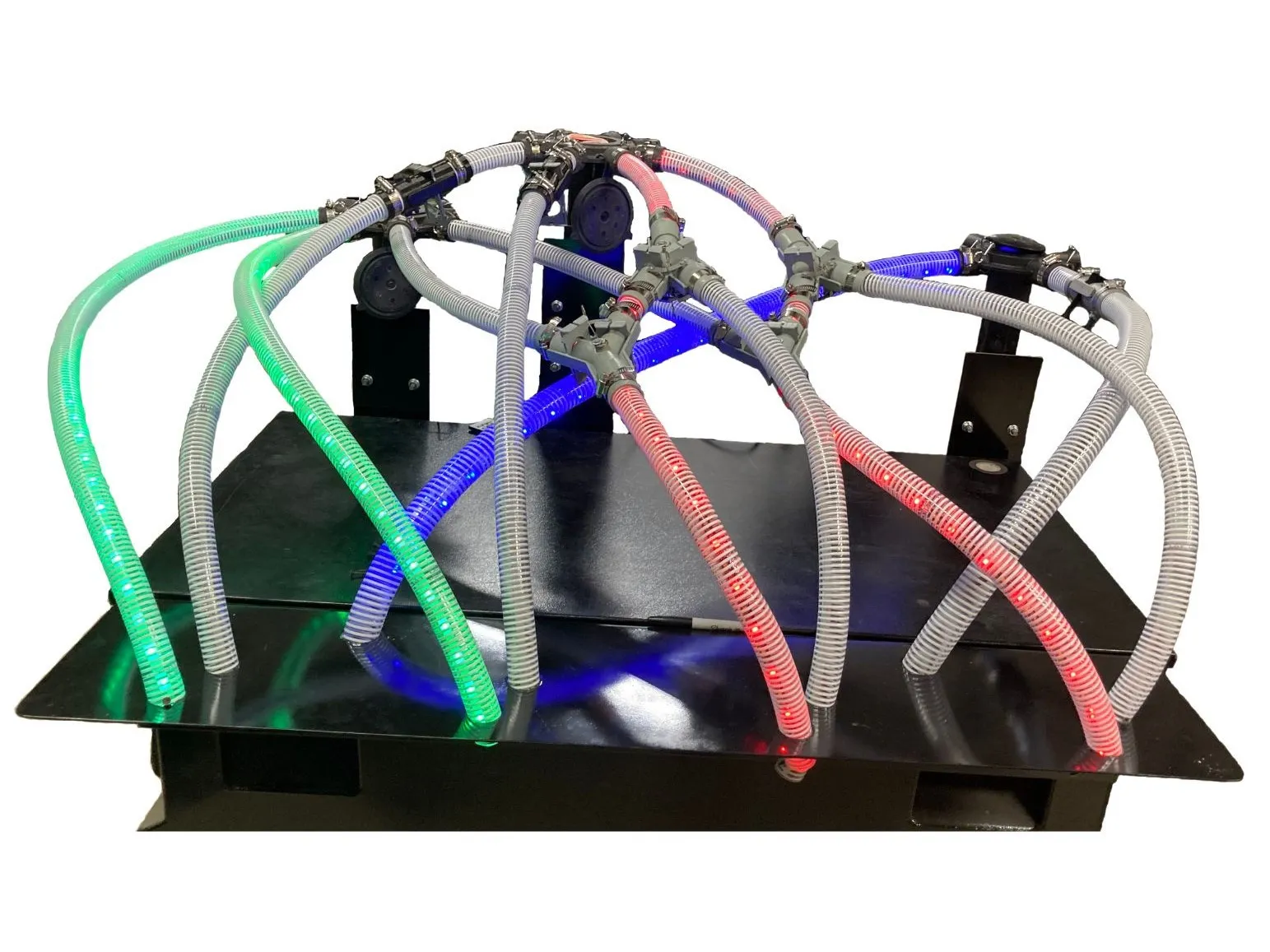

- The Flexxifinger® MultiCrop Valve™ makes it possible to convert your current air seeding equipment into an intercrop seeding tool and back into a conventional layout with minimal effort.

- The Flexxifinger® MultiCrop Valve™ will save the user time by not having to connect/disconnect hoses when switching between a conventional and an intercrop layout on the seeder. It will make it possible to seed different crops at the best depth for each crop and apply fertilizer to the crops if required, for the efficient use of seed and fertilizer.

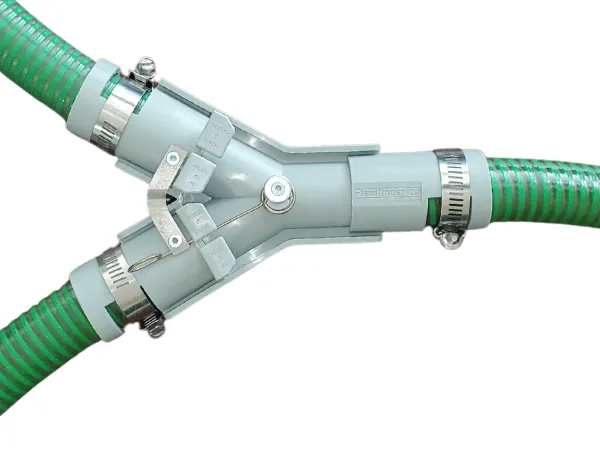

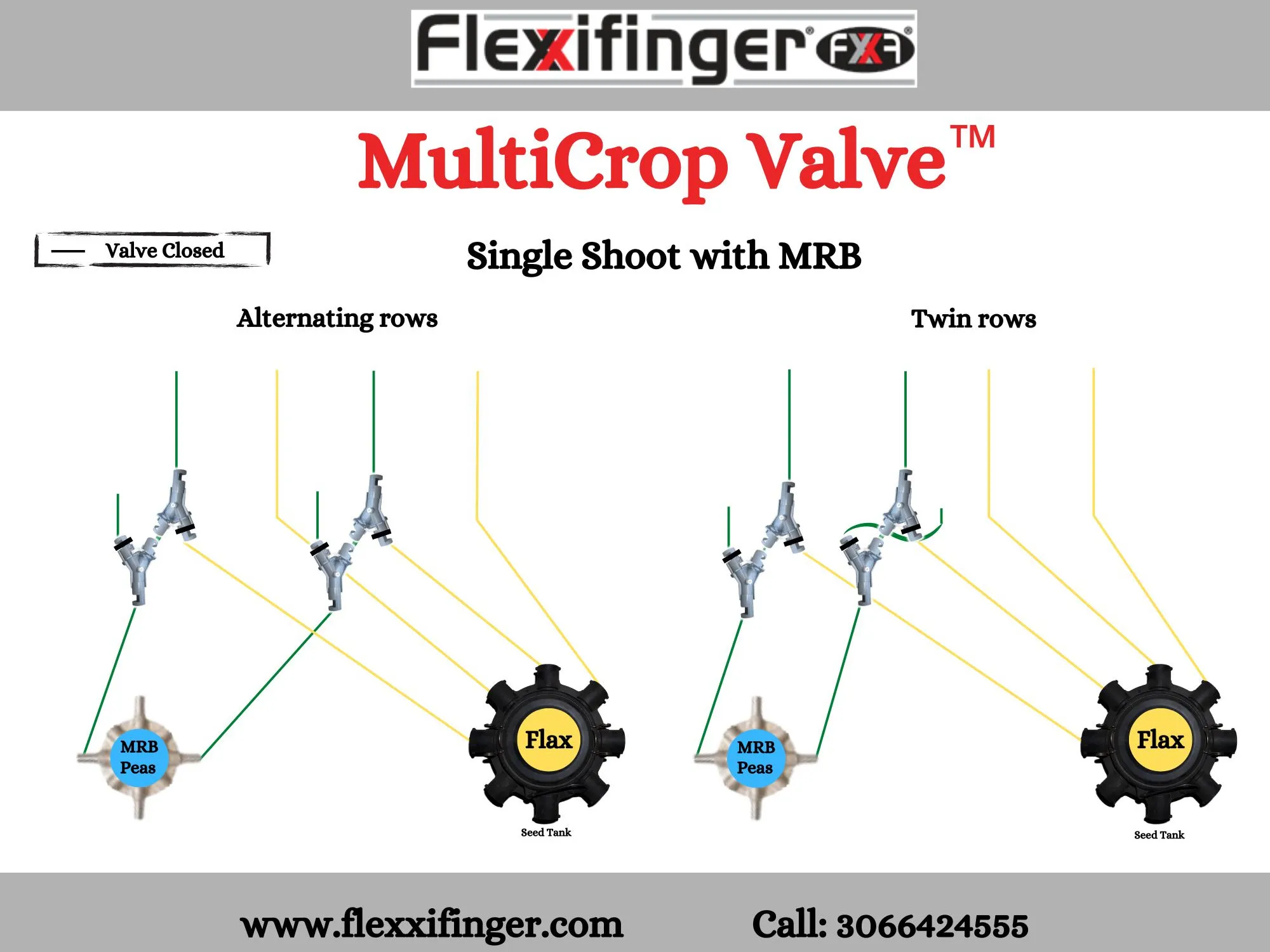

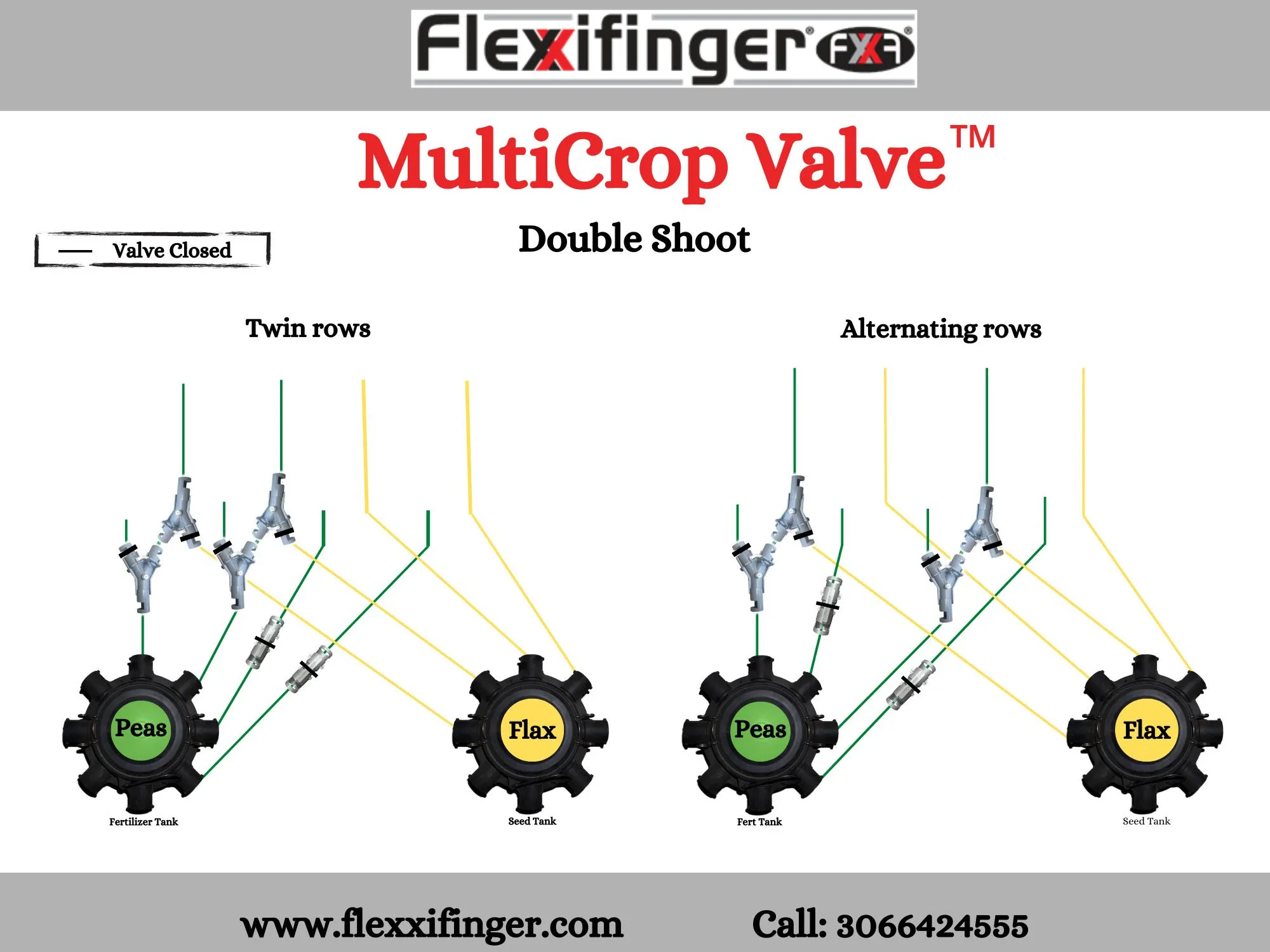

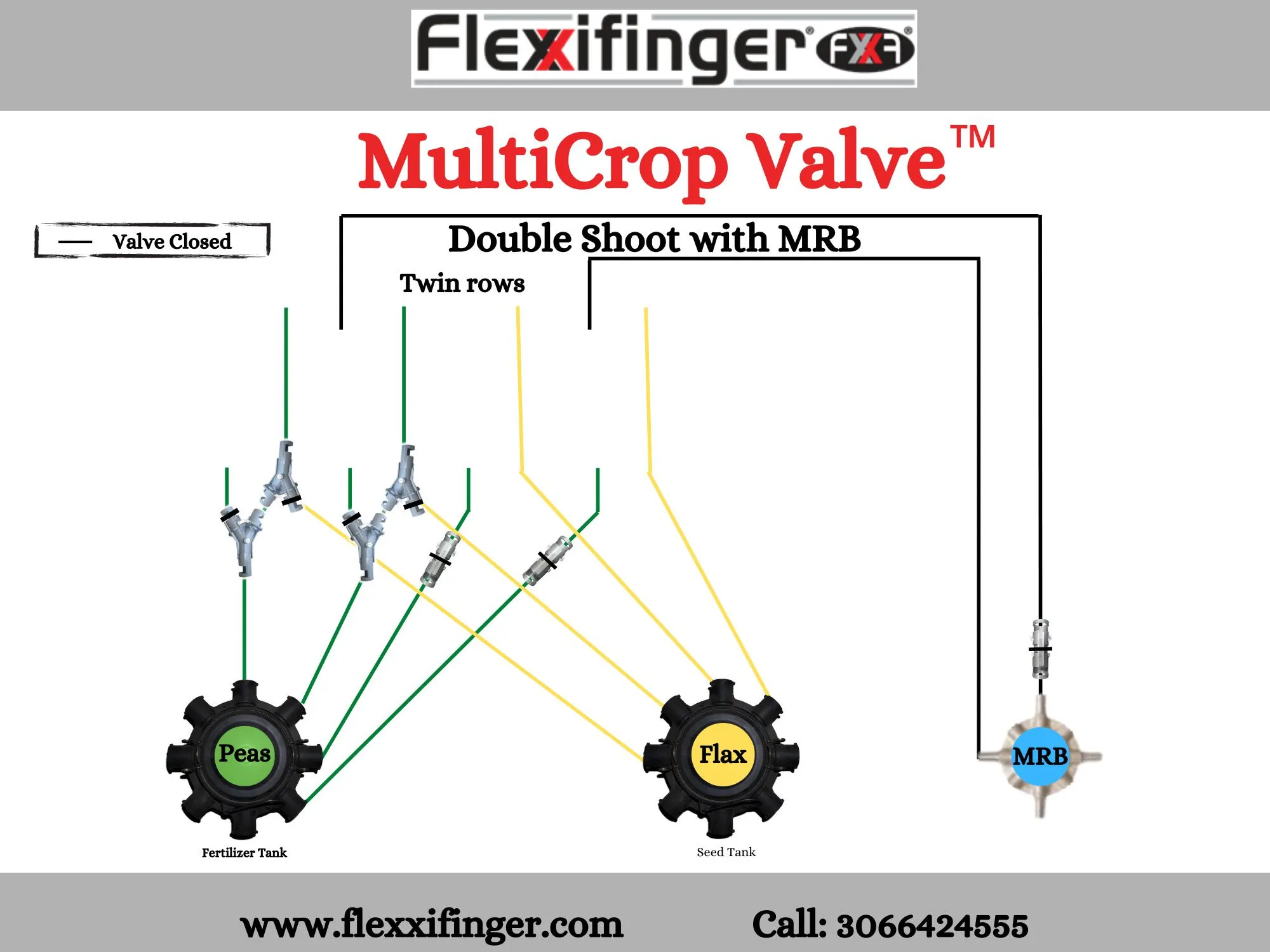

- The Flexxifinger® MultiCrop Valve™ quickly & easily converts air drills from a monocrop to a multicrop seeding unit either twin or alternating rows and back again. Supporting air packages, metering systems and air cart tanks must be available to fully implement this technology. The paired inlets of the MultiCrop Valve™ have sliding gates that select the alternate flow to the opener NO TOOLS REQUIRED.

- The air cart must be capable of at least double shoot.

Comparable Products

No Results Found